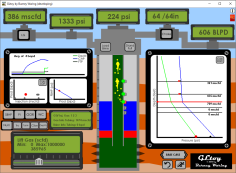

GLtoy Documentation

Copyright 2018 Burney Waring

Installing GLtoy

Using GLtoy

GLtoy Cases and Challenges

GLtoy Construction

GLtoy License

Contact Burney Waring

GLtoy Cases and Challenges

Here are detailed explanations of each of the 8 demonstration cases and the 5 challenges. This is the core of GLtoy learning, so be sure to try them all out and read my explanations.BASE CASE

Trivia: The well variables here are taken from Well 100 in Roy Strom's gas lift design manual, circa 1982. I was very amazed when GLtoy found the design to work and give almost exactly the same rates as expected.

Task 1

Unload

the well without cutting out the valves, and get it operating with

300mscf/d. To start, drag the slider in the lower left to the

right and drop the slider at a low value. If the slider does not

say "Lift Gas", click on the LG button in the upper left first.

Try not to get the message "Unloading too fast!". If you do, you have violated the API's [API RP 11V5] recommended unloading limit of 5 psi/minute up to a CHP of 300 psi and 10 psi/minute thereafter. The idea is that unloading too fast will cut out unloading valves. High velocity liquid will simply erode away the metal of the valve, and the parts there are very small. It should take a minimum of 2 hours and 10 minutes to get to 1000 psi (60 minutes to get to 300 psi, and 70 more minutes to get to 1000 psi). [At a Simulation Speed of 1, this is about 1/3 of the width on the 'real time' plot on the upper left side. That plot is 480 points wide and at a Simulation Speed of 1 represents 480 minutes, or 8 hours.]

Notice the completion brine rates. In the beginning you may have kept them below 200 blpd, but after the gas injection goes into the top valve and the pressure in the tubing falls, the rate goes up dramatically with the differential pressure across the valves.

If you want to try again, click the reset button in the lower right.

After injecting gas and after the well stabilizes, notice the average oil rate in the chart on the upper left says 90 bopd. You have successfully unloaded the well!

Task 2

Find the limits on the following variables, where this gas lift design stops working, i.e. where you can no longer unload to the third mandrel. To do this, change one of the values below and then click “Load Brine”, which will start the process over, so you can see if it is successfully unloaded. You might want to maximize the Simulation Speed so that you can check out more values more rapidly, and don't worry about the unloading rate. You can keep the Lift Gas rate at 300mscfd. Look at the liquid rate range as you change these values:

PI from 0.1 to 20.

GOR from zero to 5000

Water Cut from zero to 100%

Will gas lift still work if the well flows on its own? Try resetting the case and changing the SBHP

to 5400 psi. The well should flow. Now,

add 300mcfd of lift gas.

Does gas lift make an improvement?

In terms of Artificial Lift types, no pump design can work across these ranges. Gas lift

is very forgiving. This is an obvious

benefit, for example when either you don’t know what the well will produce, or

when you know it will change radically.

But, there are also dangers to this flexibility as you will see later.

Task 3

Until this point, we have assumed that the well stands full

before gas lifting. This is the worst

case for a gas lift design. In most cases, a well will not stand full of liquid, but instead the casing fluid will go into the

reservoir until an equilibrium is reached prior to unloading. In

some cases, the worst case for a gas lift design, the well stands full

either because of:

- A standing valves/check valve at the bottom of

the tubing, usually as a result of tubing testing with high differential

pressure or because debris is stuck around the testing plug.

- Debris/mud from the completion plugging the

screen and/or perforations

Reset the case and click the Stand Full button to see how

this affects the the liquid level and unloading. Turn on the lift gas to 300mscfd. You may notice that there is much less of a

problem with the unloading rate. This is

because when the casing is nearly full of liquid, the casing pressure increases very

rapidly due to the incompressibility of the liquid. When the casing holds a lot of gas already,

additional lift gas has to further compress the gas

in the annulus before the pressure can rise. This

slows the rate of casing pressure increase, which limits the casing

pressure, which limits the differential pressure, and thus lowers the

rate of

brine passing through the valves.

Due to the lower static gradient, the upper valves are not even necessary. If you lower the lift gas rate enough while unloading, to keep the CHP as low as possible, you will notice the top valves are not even used.

Task 4

If you are quite certain that the well will not stand full of liquid, you can greatly simplify gas lift designs by omitting upper valves. Reset the case, click on Stand Full and make the fluid level fall in the tubing. Try making the two upper valves into Dummy valves. Click on the top mandrel. It will turn red. Click on the Type button in the lower left. Slide the slider until it says "Dummy". Repeat this for the second mandrel.

Turn on the

Lift Gas and watch the CHP. It may rise

to 1440 psi since his installation has

about 1440 psi of injection pressure.

But, you can try to lower the lift gas rate to keep the CHP low,

and it can inject at the thrid mandrel with only about 1200 psi.

So, there is a good margin for omitting these valves, in this

case. And, a good reason, because a simple design

has very little that can go wrong with it.

CSG HEAD

In this next case, the BASE CASE has one change. The choke in mandrel #3 is increased from a

10/64 to a 12/64 choke. What happens?

This case demonstrates Casing Heading. This is quite a common problem. In a large field I studied in Oman, I found

that about 30% of the wells were heading.

Task 1

Notice the loss of production in this well compared to the BASE CASE. The well produces an average of only about 50 bopd in this mode, a loss of 45% of production.

Why? Think about this before reading ahead.

Notice the well is spending about half its time waiting for

the casing pressure to build up so that gas can inject again into the

tubing. The other half the time, it is injecting

downhole through the orifice valve at a high rate. This type of heading is caused by a system

imbalance between a) the rate of lift injection into the casing and b) the rate

of lift injection going into the tubing.

The casing acts as a capacitor, charging and discharging. The slugs of production will also affect

other wells in the lift gas distribution or production networks.

Task 2

What is the best way to stop this production loss? There are three methods. Try to think of them before reading ahead.Method 1

If you said to give the well more lift gas you are correct.

I managed to get the well stabilized with an extra 43 mscfd, or 14% extra. This

solves the problem very easily.

Unfortunately, even in 'optimized' gas lift fields, the

wells are often over-injected, beyond their optimum rate and gas compression is

at a maximum. Wasting 14% of lift gas in

one well is not a big deal. Wasting that

much over a whole field may mean that very good or sensitive wells get too

little lift gas, costing hundreds or thousands of bopd.

With the well producing in a stable manner, click on the "Calc LGP" button. A Lift Gas Performance curve is created, as well as an incremental liquid to injection gas ratio. The message says, "0.51 blpd/mcfd", which at 15% oil cut is 0.07 bopd/mcfd of lift gas. In other words, to add 10 more bopd might require another 140 mcfd of lift gas or 46% more lift gas. Actually, because of the non-linear nature of the curve, the blpd/mcfd figure goes down as the injection goes up. You can see this if you increase the lift gas and click the Calc LGP button again. So, you cannot get another 10 bopd, no matter how much gas you inject. In any case, we can't afford to inject extra lift gas into very many wells without buying more compression. And, that’s unnecessary.

Method 2

If you said to choke the well back, you are also correct. Many operators will choke a well back, which especially in fields with limited gas compression does work. Try lowering the wellhead choke size and see if you can stabilize the well.I managed to get the well stable at with a 18/64"

choke. Is this a good idea? Well, you have to sacrifice 16 bopd to get the well

stable. That’s an annual loss of about

US$300,000 of revenue, in this single well.

Method 3

If you said to replace the gas lift valve with the right

size seat/port/choke/orifice size, you are correct. This is

the best answer. In this case a

10/64" choke in the orifice works to stop the casing heading.

An 8/64 would allow us to cut the lift gas by 100 mscfd (saving 1/3 of

the lift gas) with a loss of 10 bopd, but keeping the well stable. Depending on the mix of wells, this may be

the optimum solution.

To change the size of the choke, click on mandrel #3, and then

on Choke in the lower left. Then slide the slider to change the

size.

Reset this case. What is the range of lift gas rates that this operation can tolerate without losing oil production with a 10/64” choke?

To me, it appears stable from 260 to 690 mscfd. Below 260 mscfd,the well will start heading. Above 690 mscfd, the next upper valve will open.

Reset this case. What

is the range of lift gas rates that this operation can tolerate without losing

oil production with a 12/64” choke, (the same as not having a choke in

a 3/16” orfice valve)?

To me, it appears stable from 343 to more than 1000 mscfd. Below 343mscfd,the well will start heading. The next upper valve does not quite open with 1000 mscfd.

Gas

lift valves and designs have a range of lift gas rates in which they

will properly operate. The range is large, gas lift is very

forgiving, but there outside this operational range you will lose

production.

Task 3

Click the reset button. Click also on the Stand Full button, so that the casing and tubing level fall. Turn the Simulation Speed up to maximum.

Change the Orifice in mandrel #3 to a 1 x 3/16 IPO valve, change it to a 7/64 choke, and change to a Test Rack Opening pressure (TRO) of 1219 psi.

What range is stable now?

To me, it appears stable from only about 295 to

312 mscfd. Outside of that range, the well either closes on that

valve or opens the valve above it. Notice the well is losing a

bit of production, about 3 bopd on the low end, if the valve is

opening and closing.

This is why you should not operate from an unloading

valve. The valve almost certainly either

will eventually erode or fatigue and fail open, but in the meanwhile you will

lose production and/or waste lift gas as the well cycles open and closed.

VALVE CUT

Turn the lift gas on and lift the well with 300 mscfd.

What? It's not doing anything? Try 700 mscfd of lift gas. OK, now its producing. Now, try turning the lift gas down to 300 mscfd. OK, the well is still working. Time to get a welltest. The well is making about 60 bopd. Does everything look OK? Pretend you are an Operator andlook at only the oil and liquid rates, the lift gas rate, and the FTP. Do you see a problem with this well? If you called the field and asked the Operator, "How is my newest well doing today?", what would they say?

They would say everything is fine, of course. Perhaps you were expecting a bit more production, but the

range of rates from wells like this vary quite a bit. And

maybe the well is still cleaning up anyway. Would

you order any further actions, like changing valves? No, you would not.

Would you order additional data gathering on this brand-new well?

Probably not. But, you should get more data on your new gas lift

well, as a matter of routine!

Look at what is going on. Everything seems fine. However, you are losing 30% of your oil production. And you wouldn't know it.

This is due to a very common problem of a gas lift unloading valve cutting out. In effect the top unloading valve has become an orifice. You saw how easy this was in the BASE CASE to unload too fast even when you were trying to control how much lift gas the well got in the unloading process. And, believe it or not, some fields with automation have no provision for regulating the ramp-up speed of their gas lift controllers, so every well gets the full lift gas straight away upon turning the well to production. This causes situations where almost every well in the field has problems with the top valves cutting out and not sealing, wasting a great amount of lift gas to very shallow and ineffective gas lift. And no one knows it. Because no one is looking for it.

A similar problem can occur if the well gets a hole in the

tubing. I know of gas lift wells that had a hole just below the tubing

hanger. They suffered on production rate and wasted a huge amount of

compression.

The problem with gas lift is that it is very forgiving. You may miss when it is not working properly.

Valves may cut-out, or wear-out, or the tubing may get some holes. These can all cause a significant loss of

production without being easily detectable from normal surface measurements. Look at this well’s CHP, FTP and LG

rate. Everything

looks normal, even the

production rate is within an acceptable range. When you make a

'target' rate for your new well, you base it off of the first welltest.

So, you are now making your target, and everyone is happy.

But the truth is you are losing a huge amount of revenue.

To monitor for hidden problems such as these, a yearly

flowing bottomhole pressure survey with stops below each mandrel should be run

in every gas lift well, to monitor for such problems.

Another, more modern, alternative is WellTracer,

which is a cost effective solution and requires no wireline intervention. It can also multiple and/or small leaks that

an FBHP survey might miss. I used to

worry that using WellTracer might cause

me to miss inflow performance issues, but knowing the lift depth and the lift

gas injection rate (also a product of a WellTracer survey) gives a model a very

good estimation of FBHP and inflow performance.

In any case, knowing where a gas lift well is lifting is a

critical part of gas lift surveillance, and one that can prevent very

significant losses in revenue when using this very forgiving artificial lift

method.

IPO UNLOAD

We already saw unloading in the BASE CASE.

This example has a more

challenging design. This well has a

higher SBHP than the BASE CASE and a lower PI. I have purposely made this the most

challenging situation by increasing the water cut to 100% and by having the

tubing stand full of liquid. This is the worst case scenario.

Unloading this well requires a few more mandrels and valves.

As you can see, the unloading process starts

with all the valves injecting brine, due to the brine covering all the valves

and there being a positive pressure difference.

When the first valve is uncovered by lowering the casing

fluid level, the pressure in the tubing drops and the difference in pressure across all the lower valves

increases quickly. You can minimize this

by lowering the lift gas injection rate, but the rate will

still be high.

As the valves are uncovered, the casing fluid level

falls. The valves uphole of this level

close. Why?

Here is the secret of gas lift using Injection Pressure Operated (IPO)

valves! Notice the closing pressures of

the valves are slightly lower at each deeper valve, relative to the casing

pressure at their depth. Another way to

say this is that the surface pressure at which each valve closes is lower for

each deeper valve.

The upper valves close when they are finished their part in

the unloading process and the casing pressure falls slightly. The lower valves

continue to inject until the casing pressure falls enough for them to close.

Why does the casing pressure fall?

Each valve has been sized such that it will pass the

'normal' amount of lift gas this well should take, in this case 340mscfd, which is the rate being

injected into the casing at the surface.

When more than one valve is open, more than this amount

leaves the casing to go into the tubing through the gas lift valves. When gas leaves

the casing at a higher rate than it enters the casing, naturally the pressure in

the casing drops. This drop in pressure

causes the higher valve to close because these are Injection Pressure Operated

valves, and it has been set to a slightly higher closing pressure. In a sense, the casing pressure is being used

by these Injection Pressure Operated (IPO) valves to coordinate their closing.

Try altering the valve TRO settings to see how this might

affect the unloading. The design still

works even with significant errors in TRO values. Try setting the valve in the second mandrel

to 1400 psi instead of 1250 psi. Then click on Load Brine. What is the result?

The well will stop unloading at the top valve. Try setting the TRO to 1140 psi. The design still works,

although any lower and it doesn’t work.

Try resetting this case and changing the PI to 10 times as

much, or a PI of 1.0. The well will

still unload to the deepest possible mandrel, which is the second mandrel.

Gas lift designs are quite forgiving. Still,

for the best results, use the best

information available. And, as I mentioned above, do some

surveillance initially and periodically on what is going on downhole to

confirm the well is doing the best that it can.

IPO KICKOFF

In this scenario, we have the same design, but due to a

shutdown, we have to start the well up again, without the brine in the

annulus. The IPO valve design works very

quickly to return the well to production.

Even if you slow the Simulation Speed to the slowest value,

it still happens quickly. If you want to

set up this case again, turn the lift gas to zero and wait for the well to

die. Then, turn the lift gas back on to

a rate of 340 mscfd. Watch it a few times and you will see that the valves

close in the order from top to bottom, just as in unloading, but in kickoff

there is no waiting for brine to move through the valves to reach deeper.

PPO UNLOADING

Watch this case and you might correctly wonder what’s going

on. The well goes very quickly go from

lifting to being dead and back again.

It’s a flicker even with the Simulation Speed turned all the way

down. These are Production Pressure

Operated (PPO) valves. They close when

the pressure in the tubing falls below their closing pressure. They reopen at a slightly lower tubing

pressure. What this means is that if gas

goes through a PPO valve it will close immediately, unless injection through

the next lower valve lowers the tubing pressure sufficiently to keep the valve

closed. This cannot happen immediately

until the brine is displaced from this well down to the next valve. So, you get the valves opening and closing

the entire time. At least this is what

GLtoy is showing. In

reality, the tubing

pressure does not change quite that quickly, so the well would inject

and partially die, then inject again. Also, the valves

themselves have some

high viscosity silicone fluid to keep them from chattering too much as

they open and close. In any case, this is not a neat process as in

the IPO valve unloading case.

PPO KICKOFF

On the other hand, PPO kickoff is much smoother. Each valve in turn closes as the valve below

it lowers the tubing pressure sufficiently.

Try resetting this case and change the PI to 1.0. The well will chatter and chatter. When it finally reaches the second mandrel,

the first valve will be chattering, and will eventually fail open, with the

same effect as the top valve cutting out.

SPACING

This case is about mandrel spacing. It a stretch to demonstrate mandrel spacing using a simulator, but I will do my best, because it is important.

Burney's mandrel spacing philosophy is that a good

mandrel spacing should:

- Unload

to surface

- Unload

to the operating depth

- Mandrels

spaced close enough together

- Have

mandrels deep enough

To achieve the above, you must have more mandrels than necessary at any one point in time, because the design needs to work over the life of the completion.

However, you should minimize the number of valves used at any one point in time, because this avoids mechanical problems of all sorts and makes troubleshooting easier.

So,

have lots of mandrels and a minimum number of valves. That's my

philosoply. To see these points, I will try to show you in GLtoy

what

happens when they are not followed, and then how to follow them very

easily.

Unload to Surface

As you load the case, you see the situation where the tubing is standing full of liquid. Unfortunately, this liquid is of too *low* of a density, which causes the pressure at the top mandrel to be too high to permit gas lift injection. Everything else in gas lift design is more conservative with a higher density, except the when calculating the static pressure gradient. In real life you might be able to fix this by opening the well to an atmospheric system pressure, using soap sticks, or nitrogen. But, it’s embarrassing.

Move the top mandrel upwards until you can inject gas, about 2519 feet.Where should the next mandrel go? It appears that mandrel #2 can be placed at about 6586 feet, since that is the intersection of the tubing pressure when lifting from mandrel #1, and the injection pressure. Change the valve in mandrel #2 to a 3/16 IPO valve. Change the valve in mandrel #3 to an Orifice.

Then, you can have mandrel #3 at about 7200 feet. And, that is about as deep as you can get

while still having sufficient injection pressure to tubing pressure

differential to inject enough gas.

Click on Load Brine and see if your mandrel spacing will work. Feel free to see if you can do better.

Close Enough Together

So, that is a very efficient design, requiring only 3

mandrels. But is this a good

design? Will it be able to handle a

variety of reservoir pressures, PIs, water cuts, GORs and rates? No.

What would happen if the PI were 8 instead of .7. That would be great! But, the well would be producing 495 bopd from

2518 feet. It would not be able to lift

from 7200 feet.

But with an extra mandrel at 5200 feet, it would produce 712

bopd. Imagine the ridiculous scenario where

you are losing 217 bopd because your design saved a mandrel or two.

Deep Enough

What happens if the SBHP declines to 2300 psi with a PI of 0.7? You would be producing 197 bopd from 7250

feet, but with a mandrel at 8700 feet you would be producing 237 bopd. For 40

bopd, you would almost certainly re-design and use wireline to change out the

valves to reach the deeper mandrel.

The most tragic example is when you have a PI that is worse

than you expected, so the rate is less and also you could lift much deeper than

you thought you would be able. This

well with an SBHP of 3500 psi and a PI of 0.2 will produce 208 bopd from the

mandrel at 7250 feet. But, it can

produce 237 bopd from a mandrel at 9200 feet.

For 29 bopd extra, you would

probably use wireline to make the change.

So, a good mandrel spacing should have a bottom mandrel two

tubing joints above the packer (for ease fishing the packer), and should have

mandrels spaced above it such that the costs and risks of wireline to install a

new design is about the same as the benefits of lifting deeper with that

design.

In my old fields, we used a spacing of about 500’ between

mandrels below the initial operating range, down to two joints above the

packer. In this well, that would mean 3

additional mandrels below 7250 feet, for example at 7880, 8510 and 9140 (even

630 foot spacing to reach 9140, two joints above the packer at 9200 feet).

Those three mandrels will certainly pay for themselves if

and when the well performance changes.

There is no perfect mandrel spacing, because things change.

You want plenty of mandrels. Mandrels are cheap compared to potential revenue loss by not having one near where it is needed.

Sometimes I hear that people use too many mandrels, thereby introducing extra (dangerous) leak paths. Mandrels do not introduce

potential leak paths, if the dummy valves use premium seals and are hydrotested

in the shop and again on the rig floor before running them. In any case, gas lift is introducing

hydrocarbons into the annulus of the well, so the additional risk for a few extra mandrels is minimal.

Insteak, you want to minimize valves installed. Many designs will work with only an orifice

or an orifice and a valve. Minimize

mechanical complexity that can result in failures to seal, failures to unload, etc.

Keep things simple, and space mandrels the easy way, see my

“Simple Mandrel Spacing.pdf”. This spacing cannot fail. I used this technique in many, many real wells, and also in the IPO and PPO

Unloading and Kickoff cases in GLtoy.

Challenges

Below are several challenges to get you thinking. Try to figure out what is going on without peeking at the answers.

The answers can be revealed by highlighting the text areas below.

Challenge 1

Is there a problem with this well? If so, is it worth fixing? Why?

The well seems to have either too small of a choke in the orifice (mandrel #3), or it is partially plugged. This is causing the upper valve to open and close. This is costing (90-80=10 bopd, at $50/bbl) a loss of revenue of $182,500 per year. While the upper valve is opening and closing (it will eventually fail), it contributes to instability in the production and injection networks, although in this case the effect is probably minor. Use the opportunity to fix this valve to lift from the next mandrel deeper, for (96 bopd) another 6 bopd, thus increasing revenue by almost $300,000 (assuming this improvement lasts only one year) at a cost of a wireline changeout of gas lift valves (onshore $50-100k?).

Challenge 2

Is there a problem with this well? If so, is it worth fixing? Why?

The second unloading valve (mandrel #2) is not functioning properly. It is either plugged or set incorrectly, or has failed closed for some other reason. Since this is a wide spacing at this depth, the well cannot unload past this valve. This is costing 32 bopd, or a revenue loss (at $50/bbl) of amost $600k per year.

Challenge 3

Is there a problem with this well? If so, is it worth fixing? Why?

Well is currently producing 137 bopd. By lifting from 9200 feet and increase injection to 700mscfd, production will increase to 272 bopd, an increase of 135 bopd, at $50/bbl, avoiding a loss of $2.4mm per year in revenue. This could be accomplished by installing a new mandrel spacing, pulling the tubing and re-running it with a different mandrel spacing. Or possibly try to punch a hole in tubing, which is a common method in low risk areas, but has also been used in very high risk areas.

http://www.alrdc.com/workshops/2005%5FSpring2005GasLift/presentations/Reviews/1%20-%20Weatherford%20---%20Pack-Off%20Presentation.pdf

http://www.alrdc.org/technicallibrary/ArticleDetails.aspx?ArticleId=1227

Lift can also be done below a packer

http://www.alrdc.com/workshops/2013_2013GasLiftWorkshop/presentations/PDF%20Versions/3%20-%203%20-%20Presentation%20---%20Weatherford%20---%20Retrofit%20Gas%20Lift%20System.pdf

Challenge 4

Is there a problem with this well? If so, is it worth fixing? Why?

The valve design has been run "upside down", e.g. with the lowest valve in the top mandrel. The well will produce 48 bopd from a valve in the bottom mandrel, a gain of 31 bopd from the current situation. Fixing this will prevent a loss of $575k of revenue per year. If the correct design was given to the wireline company, it is possible that they will pull and run the valves for free. :)

While I have consistently described the top mandrel as "mandrel #1" this is, sadly, not completely uniform across the industry. Some folks number the mandrels in the reverse order. Beware of this in communications with wireline and gas lift valve suppliers.

Challenge 5

Is there a problem with this well? If so, is it worth fixing? Why?

First, why is this well choked back and being gas lifted? That is a waste of energy that goes into compressing the lift gas, at the very least.

Second, why is this well being choked back? Every choke in the field should be reviewed several times a year, at least, to verify that it still needs to be installed. The objective should be to lower pressures in the system to maximize production. Never assume that someone had a good reason for choking back a well. If it is your well, you need to find the reason, if there is one. A well that made some water, sand, or gas years ago and was choked back is not the same well years later.

Third, why is this well being gas lifted? Well is being harmed by gas lift injection. With no choke, it can produce 2018 bopd with no lift gas vs. 1982 bopd with lift gas. Not every well in a gas lift field should get gas lift. Any reduction in the density of the production is more than offset by the extra friction in the flowlines and tubing.

Summary

So, if these sorts of problems are found in your fields, you need to ask, Why? How can these things happen, but more importantly, what can you do to prevent them from happening, and how can you spot such problems immediately, so that revenue loss is minimized? In a real situation, all wells need surveillance (to spot potential problems) and need to be optimized. In fact, optimizing only wells is really not optimizing. They are part of a whole system: Reservoir, Wells, and Facilities. If you optimize only part of a system, the result is, by definition, sub-optimum. You can see from these examples that in fields where such these problems could occur --all fields -- millions of dollars in revenue are lost if the team of engineers that manage the asset are not proactively optimizing the field, together. More information about to avoid all such loss and obtain the most value possible from any field is available in my book, Practical Optimization of Petroleum Production Systems.