ESPtoy Documentation

(Version: 26 Feb 2018)

Copyright 2018 Burney Waring

Copyright 2018 Burney Waring

Installing ESPtoy

Basics of ESPtoy

ESPtoy Details

ESPtoy Cases

ESPtoy Construction

ESPtoy License

Contact Burney Waring

ESPtoy Cases

You will find the Case Button In the bottom right of the interface, where by default it says, "Base Case". You can change to a variety of other cases by clicking to the right or left side of this button.For each of these Cases in ESPtoy, there is some sort of problem presented. Read about the problem below and see if you can determine a solution (or multiple potential solutions). The better you are able to understand and react to the problems presented, the closer you are to understanding ESPs.

Tip: When you are making a lot of changes, you should start over before you make too many and lose track. Clicking the Case button away from the case you are investigating and then back again will reset the simulation case to the original values.

I have provided 8 'Common Problems' and 7 'Challenges' for you.

For the 'Common Problems', I have included my answers (not necessarily the best answers) below. You just have to highlight the (white) text to read them.

For the 'Challenges', if you email me your answers, I will send you mine in return.

Tip: For troubleshooting in the real world, it might help you to have a diagnostic chart like this one. Many of the cases shown can be replicated in ESPtoy. Give it a try.

COMMON PROBLEMS

Base Case

This is a normal well installation. It produces about 2800 blpd. Can it be optimized?To make it more interesting, assume some limitations:

- The electrical limitations (power or current) required you to stay below 90 HZ and below 130 Amps,

- The well is prone to sand production, so you must stay above a pump intake pressure of 1000 psi

- You are not allowed to run the well run in Upthrust or Downthrust.

Answer:>> I got 3920 bpd production, so 1120 blpd more. I combined settings of HZ=83 and Choke=82% <<Answer

What changes would you make if you replaced the pump?

Answer:>> A pump with a higher catalog rate and using a lower HZ (you choose the combination) will get a pump intake of 1000 psi. At that intake pressure, the well will produce about 4800 bpd. <<Answer

Underload

This is an example of Underload. Note that this VFD will restart the well from an underload condition, but it is not very good for the ESP system to have this continue.How can the problem be fixed?

Answer:>>Lower the underload (UL) value. You also have to ensure that there is no other problem that is causing the underload condition. <<Answer

Overload

This is an example of Overload. You will have to restart the pump manually if it shuts down on overload.How can this problem be fixed?

Answer:>> It is easy to raise the overload trip level. However, usually the overload is protecting the system. You should find out what the limit is on the current for the system, i.e. the maximum amperage. Then, set the overload limit (OL) to something below this maximum, but above the normal operating current level. <<Answer

Pumpoff

This is an example of pumpoff. Why exactly does the pump stop producing? Why does it restart? What should be done? Is there a way to produce this well?Answer:>> The ESP stops on underload when gas gets into the pump because of a low casing fluid level. The gas gets to this level because the well is being pumped at a faster rate than the (low) PI can provide. When gas gets into the pump, the low mass-flow seen by the pump causes the power to fall, and thus the current to fall. The current causes an Underload condition.

You should not only change the UL setting. This will not prevent the fluid level from falling and continuing to run, which wil burn out the pump motor and possibly destroy the pump itself.

Lowering the pump rate will prevent the liquid level from falling. To do this, lower the HZ. If you lower the HZ to about 55, the pump will give about 1400 blpd. <<Answer

Worn

This is an example of pump wear. The actual rate from the well is 620 blpd, and we increased the Pump Wear value to get this match. What would the produce without pump wear?Answer:>> Pump Wear is 35%. Set the Pump Wear to zero. The rate will be about 2800 blpd. <<Answer

Viscous

This is an example of viscosity effects on the pump. Viscosity degrades the pump performance in what ways?Answer:>> If you set Viscocity to 1.0, the head will increase, the rate will increase and the BHP will decrease. Also the motor temperature will decrease. <<Answer

Gassy

This is an example of a gassy well. Note the GVF into the pump. Is this harming production? If so, how? What could you do to the ESP system, if anything, to improve this well’s performance?Answer:>> GVF in excess of 10 or 15% can harm the pump. A gas separator would be very nice to install. If you could get 85% separation (claimed by some manufacturers), you would increase production by about 700 blpd. Choking back and increasing the HZ will get the production up to about 3500. Still, at this GVF into the pump, its life may be cut short, or it may suddenly gas lock. <<Answer

Gas Lock

This is an example of gas lock. Too much gas has entered the pump and lowered the mixture SG to the point where the pump cannot generate enough head. See how the motor temperature has risen. How can you fix this? How could you prevent it?Answer:>> Turn the pump off. Lower the HZ to 56. Turn the pump back on. If things work correctly, the casing level may stay high enough to prevent the pumpoff condition that caused the gas lock. Running an ESP for very long in a gas lock condition will probably harm the pump or motor or both. The gas lock period could have been cut short by raising the underload (UL) setting. <<Answer

CHALLENGES

For the remaining Cases, I have provided a problem statement to go along with each ESPtoy Case. See if you can find an answer. Send your answers to [email protected] and I willsend you my solutions.Redesign 1

This well is producing about 1010 blpd. What is the maximum rate it can produce with a few operational changes? Decide if we should workover the well if it is producing at 50% water cut and a new ESP costs $300,000, installed by a rig. (You can try new pump sizes by changing the catalog head&rate with the grey boxes at the ends of the pump curve axes.)Redesign 2

This well has a low SBHP and low PI. I can't find a way to produce it without the pump in Downthrust. Can you?So, if the well is going to fail soon, should we redesign the pump? What would you choose for the pump characteristsics? What rate could you achieve?

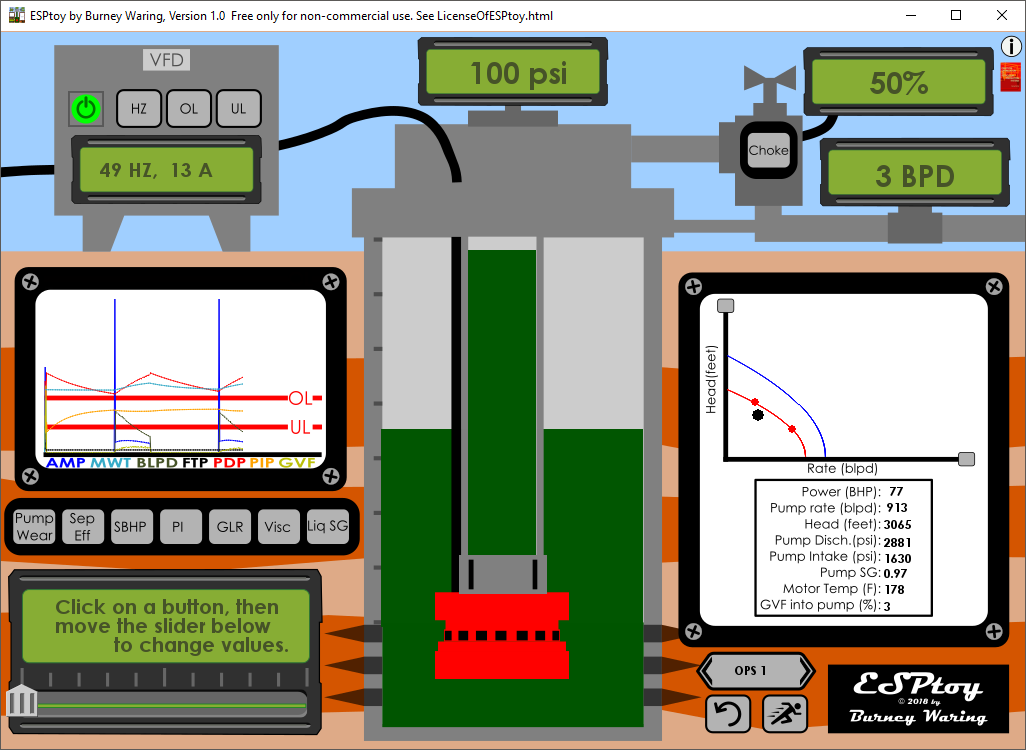

OPS 1

This well is having some big problems. How much better can you do with operational (surface) adjustments to fix them?OPS 2

This well was supposed to be a better performer, around 2800 blpd. We entered the values we expected into ESPtoy.Despite what ESPtoy says for this well, here are the actual readings:

the actual rate on this well is 1800 blpd

the actual producing Casing Level is 5800 ft.

the actual static (well off) Casing Level is 4200 ft.

the actual Current is 40A at 60HZ.

Before further analysis, match (calibrate) ESPtoy to the above data by changing only Pump Wear, SBHP and PI.

Then your boss wants to know if you can increase production up to 2800 blpd.

If so, how would you do this?

OPS 3

Help! We are totally confused. The power is on to the well, but pump is apparently not working. We tried increasing the HZ. And, we just noticed the wellhead seals are spraying completion fluid all over. And the motor temperature is very high. Looks like you have a bad installation all around. Should we call the rig back?OPS 4

The Rig just left ahead of schedule, and on to their next well. This was their fastest drilling and completion time ever!! They left the completion brine in the well full to the surface. Turn on the pump and make sure everything is OK before they leave the field. If there are any problems, please troubleshoot and report your recommendations.OPS 5

The well was producing about 3400 blpd at 28 A, a producing Casing Liquid level of 1600 and a static casing liquid level of 950 ft.Howver now it is actually producing 2400 and with current of 37A, a producing casing liquid level of 1400 and a static casing liquid level of 950 ft .

The well started producing a bit more water, although that may not be related.

Your boss says something has likely changed downhole and you need to figure out what it could be. Try changing one variable at a time and see if you can figure out what happened.